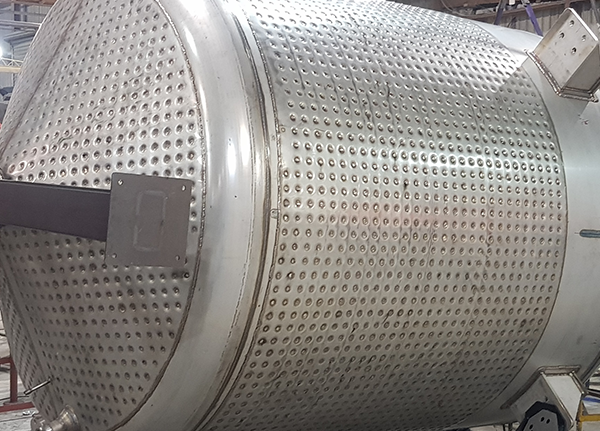

DTS, leading manufacturer of New Zealand’s on-farm stainless steel milk vats, is focused on growing into new domestic and export markets. For the past 40 years DTS has been active in the dairy industry. Now, Gavin Thwaites CEO, says the company is actively pursuing an ‘unshackling’ growth strategy.

Thwaites says the business aims to make on-farm milk vats less than 40 percent of the business mix within three years by leveraging its strengths and diversifying into new markets.

“Our core capabilities are designing and engineering food grade vats. We are very good at what we do. Our manufacturing strengths have synergies with the wine industry, brewing and other areas of food-processing.”

DTS is investigating markets in Australia and South America, and while not food-related, the company has already moved into on-farm fuel tanks manufacture for agricultural services and heavy machinery operators in New Zealand.

Thwaite says a second company-wide focus is simply “being better”.

As part of continuous improvement, DTS is inviting manufacturers, suppliers, potential customers and even competitors through the door in the coming weeks. The company’s South Taranaki manufacturing plant is earmarked as the focus of the prestigious ‘2021 New Zealand Lean Masterclass’ site tour on 1 September. Both the factory and manufacturing process will be reviewed by Lean Sensei and Kaizen Leader – Akinori Hyodo. Hyodo Sensei is a long-time Toyota Production System Leader.

Food, chemical and pharmaceutical processors and manufacturers from around New Zealand are expected to join the Masterclass to learn from the international expert, look behind the scenes at the DTS site and share ideas.

“DTS does not have a mortgage on all the good ideas. For us, the role of host site is exciting. We hope to draw on the experience of practitioners in other areas, innovate and adapt, and we welcome our competitors to join us. We are continually improving. From the point where we are today, we want to be streaks ahead in a few months’ time.”

Selection as the host site has been years in the making. Vicky Hall, Manufacturing Engineer for DTS and qualified Lean Champion attended a Lean Masterclass several years ago and saw potential in the different ways Lean could be adopted in production at DTS.

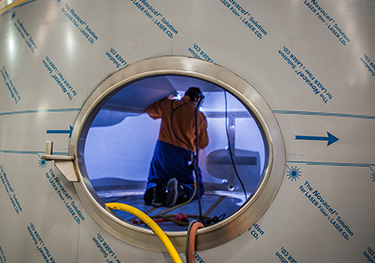

A major impact of the diversification strategy and continued lean focus is to halt the cyclic hiring of staff, upskill current staff and steadily build jobs for the local community. Currently 27 staff work at the Normanby site operating on a 10-hour four day working week and running the only Australasian laser pillow plate welder around the clock.

Immediate plans are for DTS to increase production through waste elimination and flexible assembly lines while maintaining its staffing levels. Beyond that the future looks even brighter. Thwaites says they can see the “ripple of excitement through the business” as they introduce new production lines. “There is now a high degree of optimism.”