Since the 1950s DTS have been making vats and tanks for the New Zealand food and beverage industry. We work closely with every customer to deliver a reliable design, quality fabrication and installation service.

Our food and beverage tanks meet the Ministry of Primary Industries standards for tank hygiene. Meticulously crafted with highly polished welds to reduce the risk of entrapment areas, ensuring a clean and contamination-free production environment.

OPEN FERMENTERS AND CLOSED TANKS

Choose from our pre-made tank designs, or we can personalise a tank to meet your specifications.

We can custom-build larger tanks in our workshop or on-site:

- Our workshop is equipped to fabricate tanks up to 250,000L

- Or we can build tanks above 250,000L on site if required

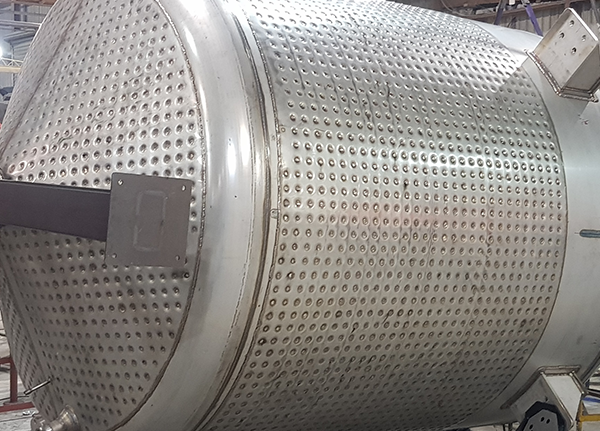

BESPOKE DIMPLE PAD DESIGN

We specialise in creating custom cooling pad designs that are tailored to fit your requirements.

We own and operate New Zealand’s only flatbed laser welder, which means our expert team can design and manufacture cooling pads that perfectly fit your tank size and requirements.

We can help you achieve substantial gains in cooling efficiency while simultaneously reducing your cooling expenses.

WARRANTY

All of our tanks come with a 60-month warranty that covers any defect in design or workmanship in the tank shell and refrigeration pads.

12-month warranty for all plastic components and product parts.

Seismic safety

DTS tanks are designed with New Zealand conditions in mind and built to meet Seismic Design standards NZS1170.5 and NZSEE2009.

STANDARD TANK SPECIFICATIONS

OPEN TOP RED FERMENTERS

|

CLOSED TOP WHITE WINE FERMENTERS

|

CLOSED TOP WHITE WINE FERMENTERS

|

|

Seismic design standards NZS1170.5,NZSEE2009 304SS Stainless steel 6” Flanged 4 leg design Rolled stainless channel base support 530x410mm Mash door, height 850mm Sample valve 4” Gullet 2” RJT bottom outlet including valve 2” RJT racking outlet including valve 1 x Thermowell 4° Flat tank floor Rolled stainless channel base support Optimised laser welded dimple pad. 1” BSPT connections |

Seismic design standards NZS1170.5,NZSEE2009 304SS Stainless steel 6” Flanged 4 leg design Rolled stainless channel base support DTS manway 600x450mm, inward opening, flush mount, entrapment design Sample valve 4” Gullet 2” RJT bottom outlet including valve 2” RJT racking outlet including valve 2 x Thermowell 4° Flat tank floor Optimised laser welded dimple pad. 1” BSPT connections Eccentric cone 420mm ID turret Laveggi D8 manway 2” Vacuum breaker valve |

Seismic design standards NZS1170.5,NZSEE2009 304SS Stainless steel Skirt to ground 30mpa Concrete pumped plinth during install Onguard seismic fasteners DTS Manway 600x450mm, inward opening, flush mount, entrapment design Sample valve 4” Gullet 3” RJT bottom outlet including valve 3” RJT racking outlet including valve 2 x Thermowell 4° Flat tank floor Optimised laser welded dimple pad. 1” BSPT connections Eccentric or concentric cone 420mm ID turret Laveggi D8 manway 2” Vacuum breaker valve |

NEED SOMETHING ELSE? WE CAN HELP

Leave your details below and we'll call you back to discuss your requirements.